Have You Discovered the Vital Role of Precision in CNC Machining?

In today's competitive manufacturing landscape, precision is more than a buzzword—it's a cornerstone of success. Computer Numerical Control (CNC) machining stands at the forefront, enabling the production of intricate parts with remarkable accuracy and repeatability. Understanding the significance of precision in CNC machining is crucial for anyone looking to elevate their manufacturing capabilities.

What Does Precision Mean in CNC Machining?

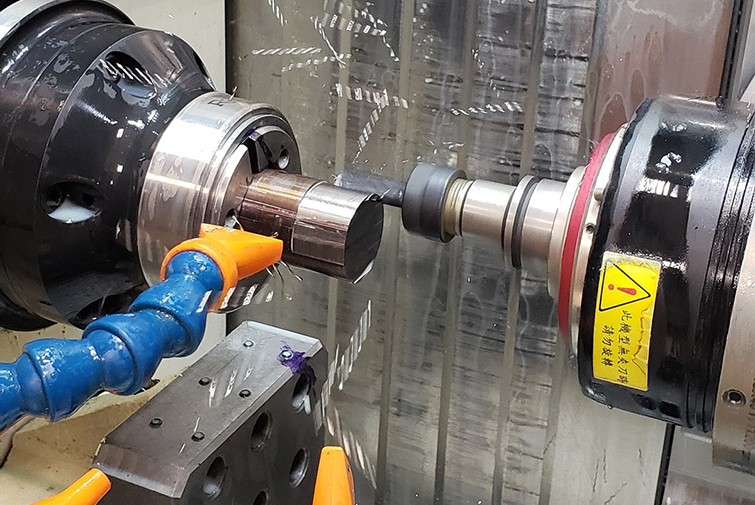

Precision in CNC machining refers to the ability to create components that meet exact specifications consistently. This entails meticulous control over the movement of cutting tools and workpieces to achieve precise dimensions, surface finishes, and tolerances. CNC machines operate based on programmed instructions, guiding cutting tools along exact paths to remove material as intended.

Accurate programming—including the right feed rates, spindle speeds, and cutting parameters—is essential for ensuring the machine performs optimally and delivers the desired results.

Why Precision Is Essential

● Meeting Specifications: Precision ensures that components fit seamlessly within their intended assemblies. A part that’s even slightly off in size can lead to assembly issues, affecting functionality. Accurate dimensions are critical to maintaining the integrity of the final product.

● Enhancing Product Quality: The quality of the finished product relies heavily on precision. Even minor deviations from specifications can result in defects, leading to safety concerns and costly recalls. High precision minimizes these risks, ensuring that the final output meets rigorous quality standards.

● Boosting Efficiency: Precision not only enhances quality but also streamlines the manufacturing process. By reducing the likelihood of errors and rework, manufacturers can improve productivity and overall operational efficiency.

Investing in Skilled Operators

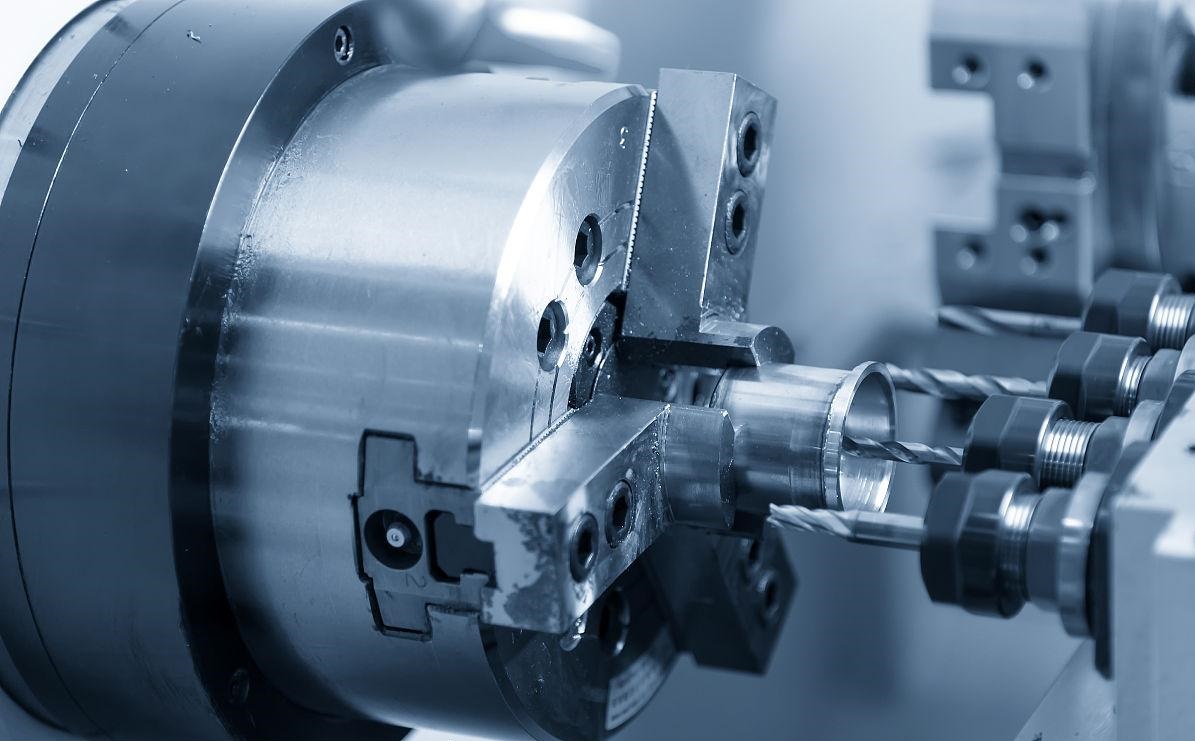

The role of knowledgeable operators is pivotal in achieving precision in CNC machining. Operators must fully understand the machine's capabilities, programming intricacies, and cutting tool selections. Their expertise is essential for identifying and resolving any issues that may arise during the machining process.

Operators also need to accurately interpret engineering drawings and specifications, comprehending the necessary tolerances that ensure optimal results. Continuous training and skill development are vital for maintaining high precision standards.

Conclusion

The importance of precision in CNC machining cannot be overstated. It serves as the foundation for quality, efficiency, and reliability in manufacturing. By recognizing the critical role of precision and investing in skilled operators, businesses can unlock new levels of production excellence.