Why CNC Machines Are So Good at Creating Different Hole Types

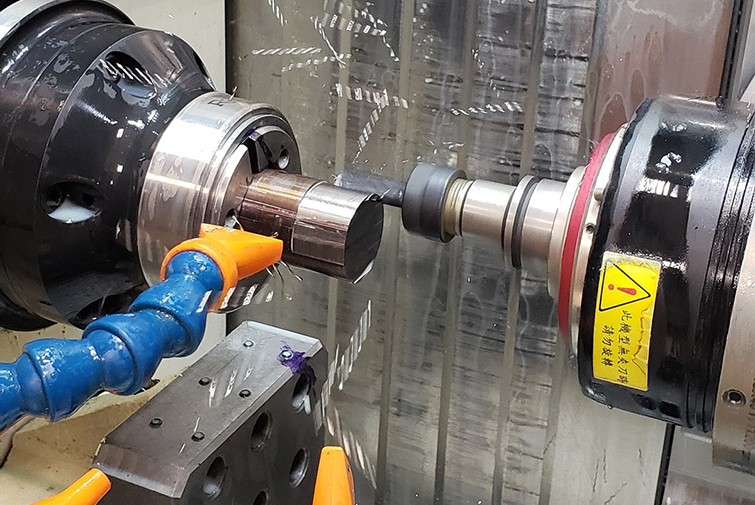

In precision machining, the ability to create various hole types is crucial for achieving optimal performance in the final product. CNC machines are incredibly versatile and accurate when it comes to drilling, boring, and creating holes in parts. But what makes CNC machines so effective at handling different hole types?

Understanding Hole Features in CNC Machining

A hole in CNC machining is not just a simple cavity; it plays a significant role in the functionality of the product. CNC machines can create a variety of hole shapes, including round, square, tapered, and oval, with incredible precision. Common methods include drilling, boring, reaming, tapping, and laser drilling. Each method serves a specific purpose and is chosen based on the design requirements of the part.

Common Types of Holes in CNC Machining

Different types of holes are used for different applications. Here are a few of the most common:

●Through Holes: Simple holes that pass entirely through the part.

●Blind Holes: Holes that do not go all the way through the material.

●Tapped Holes: Drilled with internal threads to accept screws or bolts.

●Counterbored & Countersunk Holes: Designed to accommodate screw heads.

●Tapered Holes: Widen gradually towards the base, often used for sealing surfaces.

How to Choose the Right Hole Type

Choosing the right hole type is crucial for the success of your project. Here’s a simplified guide to help you decide:

1. Purpose & Function: The intended use of the hole will dictate its size, shape, and depth.

2. Material: The type of material impacts the tools and methods used. CNC machining can handle various materials, from soft metals to tough alloys.

3. Hole Shape & Size: Common shapes include round, square, or rectangular. Select based on part function.

4. Hole Depth: Consider how deep the hole needs to be and choose the appropriate method (drilling, boring, etc.).

5. Machining Process: CNC machines can perform multiple operations in one setup, streamlining the process.

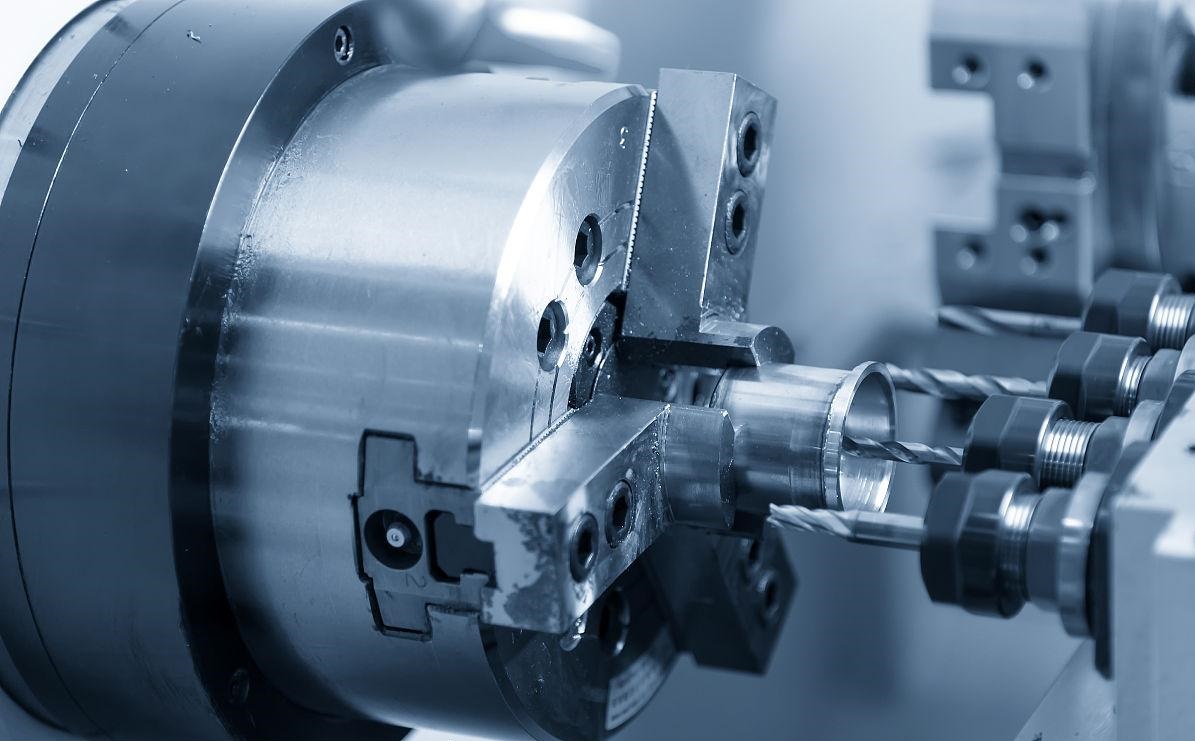

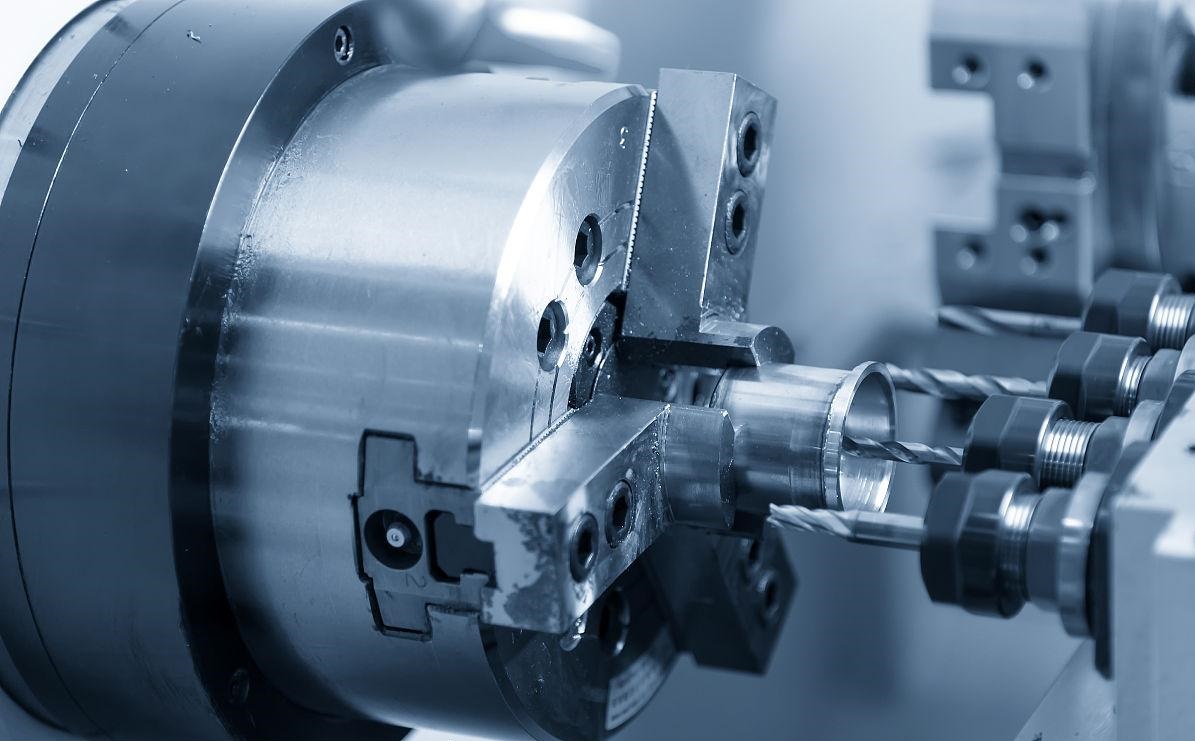

Why CNC Machines Excel at Hole Making

CNC machines excel at hole-making due to their precision and versatility. They can perform various operations—such as drilling, boring, and tapping—in one go, reducing errors and improving efficiency. The automation reduces human error, ensuring consistency and repeatability. CNC machines can also handle complex hole geometries and tight tolerances, making them ideal for both small runs and mass production.

Conclusion

CNC machines provide unmatched precision and flexibility in creating a wide variety of hole types. By choosing the right type of hole and using CNC technology, you ensure that your product performs as intended.

At Pincheng, we offer high-precision CNC machining services for various hole types, from simple drilled holes to intricate tapered cavities. With our expertise, you can trust us to deliver excellent results for all your machining needs.